The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

Putting a bend on a curve sheet steel.

If your bend radius needs to be adjusted a member of engineering design services team will contact you before your design is manufactured.

To bend sheet metal in a vice start by marking a line on the metal where you want to bend it.

Use a dry erase marker to make the mark.

The tighter the radius the bigger the opposing forces become bringing up the concept of minimal radius.

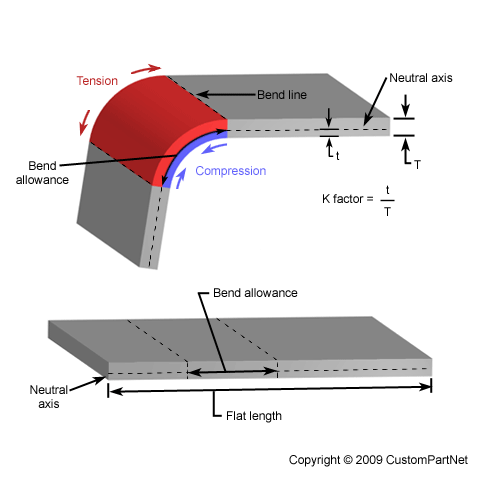

When steel plate is bent the inside surface of the bend is compressed and the outside surface of the bend is stretched.

Showing how i bend steel plate without using a brake.

I ll be bending the metal using a jig just like the one in this ible i m a big fan of atomic zombie s builds.

The average hack requires at least one angled metal part and the best tool to make one is still the good ol press brake.

If your sheet metal is long ask a friend to stabilize the part hanging out from the form blocks so it doesn t affect the bend.

This way you won t need to be concerned about making an unwanted mark.

Step 1 measure and marking your sheet metal.

It s important that the person doing the bending maintain equal tension across the bend and not to move too quickly.

Update check out this super two person trike my partner and i are offering on kickstarter.

Take your time and keep moving toward the.

Here s how you can bend your sheet metal like a pro.

Before attempting to make your bend you ll need to measure and mark the place where you want to make your bend on your sheet metal.

Except i like curved lines once in a while.

Showing how i bend steel plate without using a brake.

Somewhere in between lies the neutral axis which is a line in the steel that is neither compressed nor stretched.

Forming radius bends in sheet steel would normally be done with slip rolls but acceptable work for a lot of jobs can be done using a piece of pipe.